CLIMATE

TESTS

The climatic chamber of the German company Feutron allows us to simulate the conditions of transport, installation and operation of fiber optic splice protectors at temperatures from -75°C to + 180°C. An additional function of the chamber is the possibility of testing products in relative humidity conditions from 10 to 95%.

VIBRATION

TESTS

The vibration system of the German company RMS allows us to subject our products to shock, vibration (sinusoidal, random) and impact tests. The above tests simulate the conditions of transport, installation and operation of fiber optic splice protectors.

CORROSION

TESTS

We use laboratory corrosion tests to select materials, as well as to control the processes taking place in the structure of materials used for the production of fiber optic splice protectors exposed to various weather conditions.

STRENGTH

TESTS

We have the ability to test the mechanical properties of the connections of the optical fiber with the fiber optical splice protector. We check the influence of the twisting of the optical fiber in relation to the protector, the holding force of the optical fiber in the protector and the impact of the crushing moment on the protector.

see more

LOSSES

TESTS

One of the most important tests to which fiber optic splice protectors are subjected are optical power loss measurements. The power loss is quantified with a quantity called the attenuation, which is expressed in dB. One of the methods of determining the attenuation is a measurement method called insertion.

OTDR

TESTS

Fiber optic reflectometer is the basic measuring device used to determine the quality of the installed elements on the fiber optic line. Undoubtedly, the inseparable connections (fiber optic splices) protected by the fiber optic splice protectors are such elements.

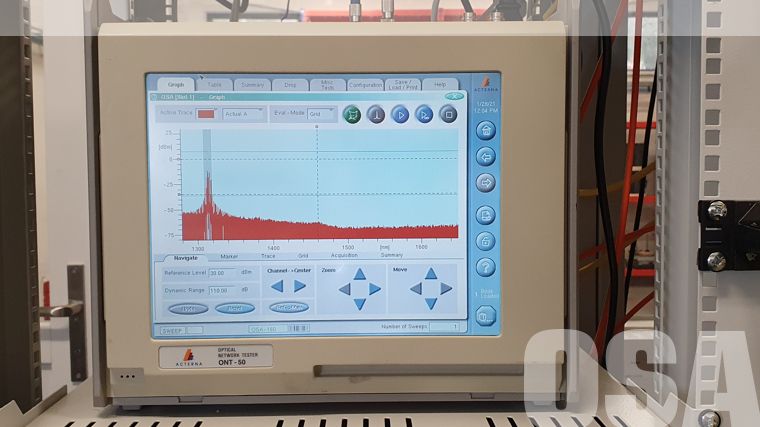

SPECTRUM

ANALYSIS

The optical spectrum analyzer gives the opportunity to obtain information about the waveform / quality / state of the spectrum of the optical signal after passing through the passive and active elements of the optical line. The changed, deteriorated image of the spectrum affects the quality and distance of data transmission.

SPLICING

FIBERS

We have the latest equipment for splicing optical fibers. Listening to the needs of installers, we meet them by offering protectors that perfectly cooperate with the latest generation of devices for splicing optical fibers.

HUMIDITY

TESTS

The production of components of heat shrink fiber optic protectors, such as hot-melt or heat shrink tubes, requires the control of the humidity content in the granules. Granules tend to absorb humidity from the air.

VISCOSITY

TESTS

One of the components of aluminum, crimp fiber optic splice protectors is a modified polyisobutylene mass (PIB). It protects the fiber optic splice against climatic factors, pollution and mechanical damage. It stabilizes the optical fiber in a specific location, not allowing it to move.