STRENGTH TESTS

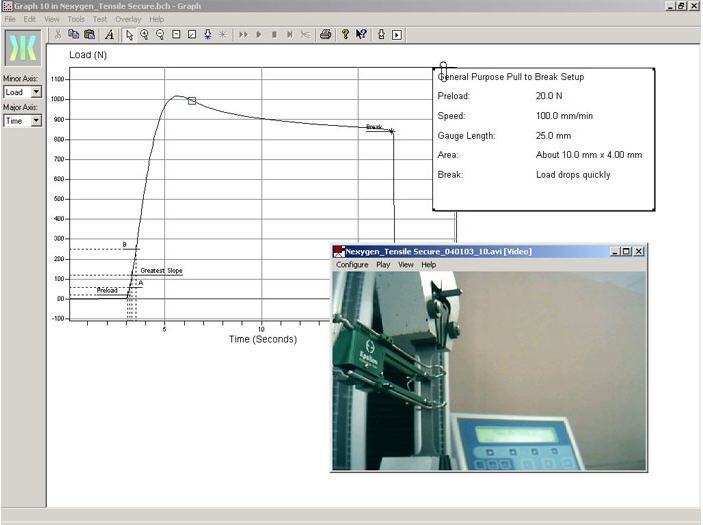

We have the ability to test the mechanical properties of the connections of the optical fiber with the fiber optical splice protector. We check the influence of the twisting of the optical fiber in relation to the protector, the holding force of the optical fiber in the protector and the impact of the crushing moment on the protector. The above tests are enabled by the LRX device from the American company Ametek Lloyd Instruments. Features of the device: Maximum compressive and tensile force 2500N, length of the working column 750mm, operating speed from 0.01 to 1020mm / min. All tests are supported by NEXYGEN MT 4.0 software. NEXYGEN is a material testing and data analysis program. It allows the operator to control and monitor all aspects of the system, ensuring fast, reliable and efficient testing and data analysis for tensile, compression, peel, tear, creep, relaxation and bend tests.

Using the LRX system, we test fiber optic splice protectors in accordance with the following requirements:

EN 50411-3-3 European standard

- Criterion 8.3.5: EN 61300-2-5, Torsion: magnitude of load 2N, rotation angle +/- 180°, 10 cycles, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.6: EN 61300-2-4, Fiber/Cable retention: magnitude of load 2N, 60s, 1 cycle, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.7: EN 61300-2-7, Bending: magnitude of load 2N, 5s, 1 cycle, 1310&1550&1625nm δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices,

Norma Niemieckiej Telekomunikacji TS 0338/96

- Criterion 5.9.8: TS 0338/96, Tensile strength: magnitude of load 5N, 60s – fiber protrusion ≤ 0.6mm, magnitude of load 25N, 60s – fiber protrusion > 2,5mm,

- Criterion 5.10.2: TS 0338/96, Vertical bending: 6N, deformation of width ≤ +/- 0,2mm, deformation of height ≤ +/- 0,5mm,

- Criterion 5.10.3: TS 0338/96, Horizontal bending: 2N deformation of width ≤ +/- 0,2mm, deformation of height ≤ +/- 0,5mm,

- Criterion 5.10.4: TS 0338/96, PIB mass control: Pressure force from 200 to 500N, 100s, pressure speed 6mm/min, penetration of the stamp into the PIB mass 0,5mm. Pressure force after test from 50 to 200N.