PIPE

EXTRUSION

We extrude pipes ourselves for the production of heat shrinkable fiber optic splice protectors. We have three complete lines for the production of thermo-fusible inner pipes and pre-pipes for heat-shrinkable outer pipes.

WIRE

CUTTING

We straighten and cut the wire for the production of heat shrinkable fiber optic splice protectors. We have five complete lines equipped with the most modern equipment that allows you to control almost all parameters of straightening and cutting. Precise pneumatic feeders allowing the length of the cut wire to be kept constant.

CONFECTION

OF PROTECTORS

All heat shrinkable fiber optic splice protectors are hand-assembled from materials that we produce ourselves. Each component of the product is repeatedly reviewed and assessed by employees before it goes to packaging.

ANT

PRODUCTION

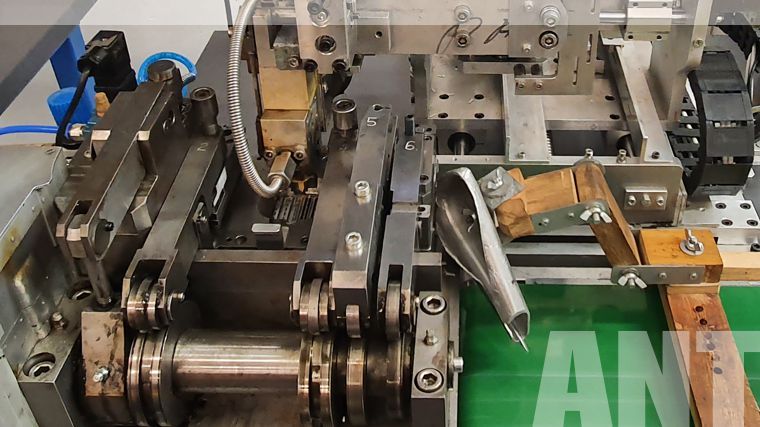

In our company, we also produce aluminum, crimped ANT series fiber optic splice protectors. For this purpose, we use a machine designed and manufactured by our engineers.

PRODUCTION

OF BLISTERS

For packing the ANT series protectors, we use blisters that we produce ourselves in our company on a semi-automatic thermo-molding machine. The machine allows us to form blisters with dimensions of 370 x 240 mm. Each blister is viewed and assessed by an experienced worker. We can make the packaging according to the customer’s request.

PACKING

AND SHIPPING

Heat shrink splice protectors we pack 1000pcs to one carton. Usually it is 10 string bags contain 100 protectors each. Crimped, aluminum ANT protectors are packed in one carton after 150pcs.