Series VMF

( flexible fusion ) Product code: VMF-L-XX

Product code: VMF-L-XX

HEAT SHRINK FIBER OPTIC SPLICE PROTECTORS

Series VMF

| Part No. | D | L | d | EN 50411-3-3 |

| VMF-10-XX | 1,2 | 10 | 0,5 | * |

| VMF-15-XX | 1,2 | 15 | 0,5 | * |

| VMF-20-XX | 1,2 | 20 | 0,5 | * |

| VMF-25-XX | 1,2 | 25 | 0,5 | * |

| VMF-30-XX | 1,2 | 30 | 0,5 | * |

| VMF-35-XX | 1,2 | 35 | 0,5 | * |

| VMF-40-XX | 1,2 | 40 | 0,5 | * |

| VMF-45-XX | 1,2 | 45 | 0,5 | * |

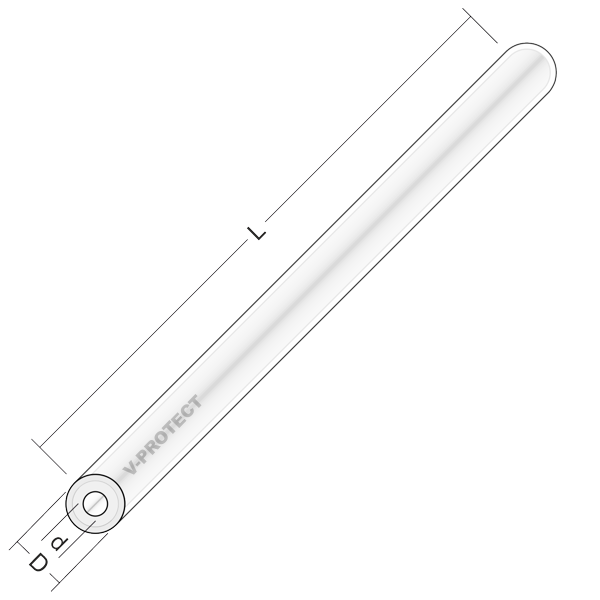

D – Outer diameter after recovery

L – Length after recovery

d – Hole diameter before recovery

XX – Color

S1 – Heat shrink single fiber

P – Primary coated 125/200µm or 125/250µm

XX6 – Color according to EN 50411-3-3

PRODUCT IN VIPro PROGRAM

The product is covered by the VIPro Loyalty Program.

For each ordered package of 1000 pcs you get 5 VIPro points.

AVAILABLE COLORS

XX – color description – XX6

00 – transparent – 00

FULL COLORS

01 – black – 10

02 – brown – 11

03 – red – 03

04 – orange – 07

05 – yellow – 02

06 – green – 05

07 – blue – 01

08 – purple – 06

09 – grey – 08

10 – white – 04

11 – pink – 12

12 – turquoise – 09

TRANSPARENT COLORS

51 – black

52 – brown

53 – red

54 – orange

55 – yellow

56 – green

57 – blue

58 – purple

59 – grey

61 – pink

62 – turquoise

Other colors are available on request.

HOW TO ORDER

VMF-35-00(100) – 100pcs packed to one zip-bag (Standard packing)

VMF-35-00(50) – 50pcs packed to one zip-bag

* Other packing method are available on request.

PACKING

The carton contains 1000 pcs fiber optic splice protectors. Standard packing consists of 10 zip bags with 100pcs of protectors each.

Other packaging methods are available on request.

PRODUCT DESCRIPTION

VMF Mini FLEX Series fiber optic splice protectors have found their place in the production of laser modules, In-Line attenuators, Mode Conditioning Patchcords (MCP), etc. In order to reduce the diameter of the sheath after shrinking, the reinforcing wire has been omitted. The thickened wall of the outer jacket and the outer tube is responsible for stiffening the connection. They are used wherever there is limited installation space. Small size and flexible connection are the main advantages of this solution. Excellent climatic and thermal properties predispose them for use both in closed and open spaces. At the design stage, the main objectives were: full protection of the welded optical fibres and small size after shrinking. In the production process, attention has also been paid to the initial shrinking of the sheath so as to eliminate the gap between the coatings. This protects the sheath against the loss of the inner coating and facilitates the insertion of the optical fibre. The final product is checked to meet the requirements set by the EN 50411-3-3 European Standard and GR-1380-CORE American Standard and ZN-96TPSA-006 standard of Polish Telecommunications. The sleeves we produce offer full protection to the fiber optic splices. They do not cause additional insert losses, and they offer protection against mechanical damage, pollution and weather conditions.

The VMF series is characterised by a small outer diameter (after shrinking D=1.2mm) and reduced length (the shortest L=10mm). The structure of the sheath consist of: an outer sheath with thickened wall and an inner sheath with a 0.5 mm opening. The protectors are dedicated to primary coated 250µm (fiber). The internal tube is made from special material with good adhesion to many materials and low solubility in water. It changes its consistency to semi-liquid in growth temperatures. This enables the space between the inner wall of the outer sheath and the optical fibre to be thoroughly filled, eliminating the formation of air bubbles. The outer sheath material guarantees durability as well as tensile and puncture resistance. It is characterised by optimum air permeability, high gloss and a smooth surface.

PRODUCT PROPERTIES

- Outer diameter after recovery: 1,2 mm +/- 0,1mm *

- Hole diameter before recovery: 0,5 mm + 0,1mm *

- Lenght of the protector after recovery: L +2/-1mm *

- Minimum installation temperature: 110 °C

- Max installation time: 60 seconds

- Standard color: transparent

- RoHS compliant

- Packing: 100pcs packed to one zip-bag (other packing method are available on request)

* – Tolerances in accordance with the requirements of EN 50411-3-3

REFERENCES

European standard EN 50411-3-3

- Criterion 8.3.1: EN 61300-3-3; Change in attenuation: 1310&1550nm δIL ≤ ±0,1dB per circuit of 5 protected fusion splices

- Criterion 8.3.3: EN 61300-1-1; Vibration: 10-50Hz, amplitude 0,75mm, 15 cycles, 1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.5: EN 61300-2-5, Torsion: magnitude of load 2N, rotation angle +/- 180°, 10 cycles, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.6: EN 61300-2-4, Fiber/Cable retention: magnitude of load 2N, 60s, 1 cycle, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.7: EN 61300-2-7, Bending: magnitude of load 2N, 5s, 1 cycle, 1310&1550&1625nm δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.8: EN 61300-2-17, Cold: -40°C, 96h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.9: EN 61300-2-18, Dry heat: +80°C 96h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.10: EN 61300-2-19, Damp heat: from +25°C to +55°C, 93%Rh, 4 cycles, 96h 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.11: EN 61300-2-22, Change of temperature: from -40°C to +70°C, 12 cycles, 68h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.12: EN 61300-2-26; Salt mist: concentration NaCl 5%, +35°C 96h 6.5÷7.2PH, 1 cycle, 1310&1550&1625nm δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices. Additionally, there are no noticeable significant differences in the appearance of the tested product, such as traces of rust, discoloration, deformation.