Series ANT

( fast installation ) Product code: ANT-L-XX

Product code: ANT-L-XX

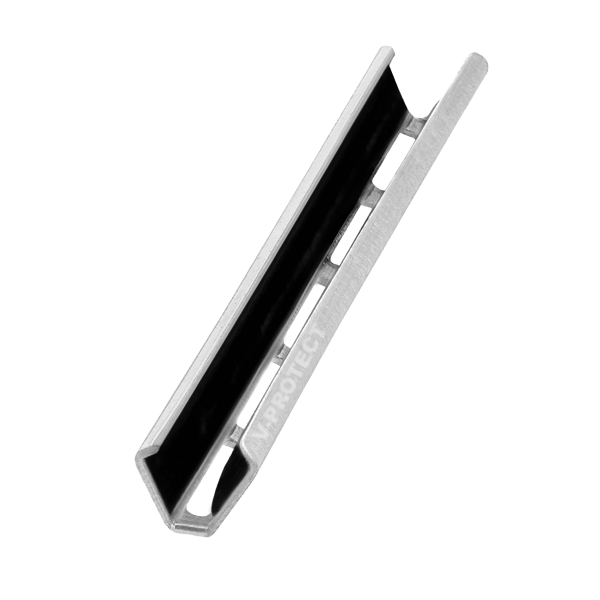

ALUMINIUM, CRIMP FIBER OPTIC SPLICE PROTECTORS

| Series ANT | |||||

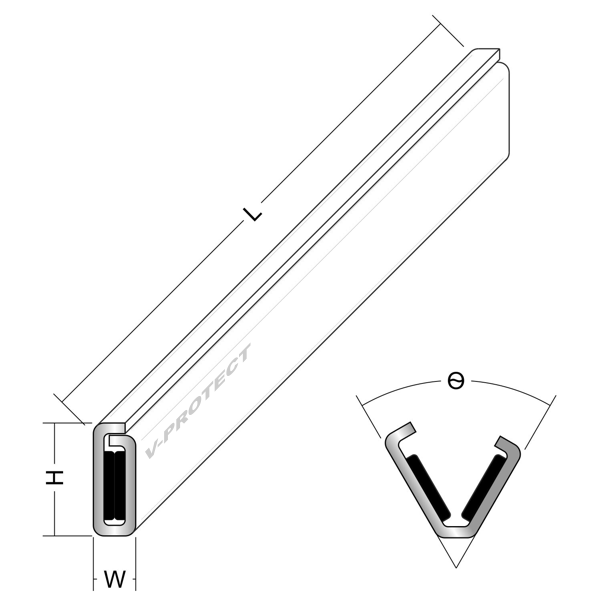

| Part No. | W | H | L | θ | EN 50411-3-3 |

| ANT-30-00 | 1,2 | 3,2 | 30 | 60° | F1-NA-30-P-00 |

W – Width of the protector after crimping

H – High of the protector after crimping

L – Lenght of the protector after crimping

θ – Angle of the protector before crimping

F1 – Aluminium, crimp protectors for single fiber

P – Primary coated 125/200µm or 125/250µm

PRODUCT IN VIPro PROGRAM

The product is covered by the VIPro Loyalty Program.

For each ordered package of 150 pcs you get 8 VIPro points.

PRODUCT DESCRIPTION

Fiber optic splice protectors series ANT are applied in nearly all branches optic fibers engineering. They are used to protect fiber welds in fiber optic splice closures as well as 19″ rack fiber optical distribution panels, stand and wall boxes. Small size, tightness of connection and speed of installation are the main advantages of this solution. Excellent climatic and thermal properties make it ideal to use in closed and open spaces. The main goals during design phase were: full protection of the fiber optic splices, small size after crimping and short installation time. The final products are checked for compliance with the requirements set out in TS 0338/96 Deutsche Telekom and EN 50411-3-3 European Standard. The sleeves we produce offer full protection to the fiber optic splices. They do not cause additional insert losses, and they offer protection against mechanical damage, pollution and weather conditions.

Series ANT has a small external dimensions (L = 30mm, H = 3.2 mm, W = 1.2 mm). The protector consist of: a 0.3mm thick aluminum body and 0.3mm thick butyl strips (PIB mass). This solution allows the use of the protector to fibers with a coating of 250um or smaller. The mass strips are made of butyl mass with very good adhesion to many materials and low solubility in water. Aluminum body reinforcing stiffener connection is made from high quality aluminum strip. When crimping the protector, the optical fiber is tightly immersed in the mass filling the space between the fiber and the aluminum body. This casing design eliminates air bubbles. It also prevents transverse and longitudinal stresses in the weld splice during the clamping process. Stresses significantly increase the insertion and reflection loss of the connection. In extreme cases, they can lead to breaking the connection, which means repeating the welding procedure. The protector guarantees durability and resistance to crushing, stretching and puncture.

PRODUCTU PROPERITIES

- High of the protector after crimping: H=3,2 mm +/-0,1mm *

- Width of the protector after crimping: W=1,2mm +/-0,1mm *

- Lenght of the protector after crimping: L=30mm +/-0,5mm *

- Opening angle of the protector before crimping: θ=60° +0/-5° *

- Mechanical protection

- Flexible laying

- Waterproof and hermetic protection

- Very short installation time

- RoHS compliant

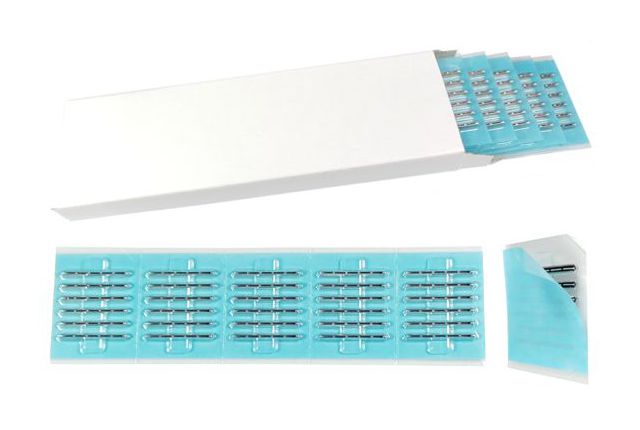

- Packing: 150pcs to one carton

* – Tolerances in accordance with the requirements of EN 50411-3-3

PACKING

Packing: 150 pcs in one paper carton. Carton including five blisters of 30 protectors. One blister is made of five columns that can be separated. Each column contains 6 protectors and is closed with a reusable tape

HOW TO ORDER

ANT-30-00(150*) – 150pcs packed to one carton (Standard packing*)

ANT-PT – ANT Pressing tool

* Other packing method are available on request.

REFERENCES

European standard EN 50411-3-3

- Criterion 8.3.1: EN 61300-3-3; Change in attenuation: 1310&1550nm δIL ≤ ±0,1dB per circuit of 5 protected fusion splices

- Criterion 8.3.3: EN 61300-1-1; Vibration: 10-50Hz, amplitude 0,75mm, 15 cycles, 1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.5: EN 61300-2-5, Torsion: magnitude of load 2N, rotation angle +/- 180°, 10 cycles, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.6: EN 61300-2-4, Fiber/Cable retention: magnitude of load 2N, 60s, 1 cycle, 1310&1550&1625nm δIL ≤±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.7: EN 61300-2-7, Bending: magnitude of load 2N, 5s, 1 cycle, 1310&1550&1625nm δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices,

- Criterion 8.3.8: EN 61300-2-17, Cold: -40°C, 96h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.9: EN 61300-2-18, Dry heat: +80°C 96h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.10: EN 61300-2-19, Damp heat: from +25°C to +55°C, 93%Rh, 4 cycles, 96h 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.11: EN 61300-2-22, Change of temperature: from -40°C to +70°C, 12 cycles, 68h, 1310&1550nm δIL ≤ ±0,2dB durin -, δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices

- Criterion 8.3.12: EN 61300-2-26; Salt mist: concentration NaCl 5%, +35°C 96h 6.5÷7.2PH, 1 cycle, 1310&1550&1625nm δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices, additionally, there are no noticeable significant differences in the appearance of the tested product, such as traces of rust, discoloration, deformation.

TS 0338/96 Deutsche Telekom standard

- Criterion 5.8: Transport simulation: from -40°C to +85°C, 20 cycles, 183h,

- Criterion 5.9.1: TS 0338/96, EN 61300-3-3; Change in attenuation after installation: 1550 δIL ≤ ±0,1dB after – per circuit of 5 protected fusion splices for criterions 5.9.2, 5.9.3, 5.9.4 i 5.9.5 and δIL ≤ ±0,1dB after – per circuit of 12 protected fusion splices for in other tests where the measurement of the change in attenuation is required,

- Criterion 5.9.2: DIN EN 61300-2-18, Dry heat: +85°C 96h, 1550nm IL ≤ 0,1 for 5 crimp protectors,

- Criterion 5.9.3: DIN EN 61300-2-17, Cold: -45°C, 96h, 1550nm IL ≤ 0,1 for 5 crimp protectors,

- Criterion 5.9.4: DIN EN 61300-2-19, Damp heat: +40°C, 93%Rh, 96h, 1550nm IL ≤ 0,1 for 5 crimp protectors,

- Criterion 5.9.5: DIN EN 61300-2-22, Change of temperature: from -40°C to +70°C, 12 cycles, 68h, 1550nm IL ≤ 0,1 for 5 crimp protectors,

- Criterion 5.9.6: EN 60068-2-6 , Vibration: 10-500Hz, 10 cycles, 1550nm IL ≤ 0,1 for 12 crimp protectors,

- Criterion 5.9.7: EN 60068-2-27, Shock: 11ms, half sine 15G, 1550nm IL ≤ 0,1 for 12 crimp protectors,

- Criterion 5.9.8: TS 0338/96, Tensile strength: magnitude of load 5N, 60s – fiber protrusion ≤ 0.6mm, magnitude of load 25N, 60s – fiber protrusion > 2,5mm,

- Criterion 5.10.2: TS 0338/96, Vertical bending: 6N, deformation of width ≤ +/- 0,2mm, deformation of height ≤ +/- 0,5mm,

- Criterion 5.10.3: TS 0338/96, Horizontal bending: 2N deformation of width ≤ +/- 0,2mm, deformation of height ≤ +/- 0,5mm,

- Criterion 5.10.4: TS 0338/96, PIB mass control: Pressure force from 200 to 500N, 100s, pressure speed 6mm/min, penetration of the stamp into the PIB mass 0,5mm. Pressure force after test from 50 to 200N.

- TEST_REPORT_ANT_EN.pdf